What is the Difference Between a Screwdriver and an Impact Driver?

posted in Industrial Equipment by admin

When it comes to hardware tools, selecting between the cutting-edge Bosch Cordless Impact Driver and a conventional screwdriver has significant effects on task convenience and efficiency. Though these tools all aim to drive screws into various materials, there are notable differences between them in terms of appearance, use, and efficiency. This investigation seeks to shed light on the subtle distinctions between them, providing an understanding of their unique characteristics, uses, and the revolutionary impact of cordless technology on the market for traditional screwdrivers.

Conventional screwdrivers have long been essential instruments in the toolbox since they are manual in function. Their simplicity is demonstrated by the simple rotating force that the user applies. By way of contrast, this technique is revolutionized by the Bosch Cordless Impact Driver, a sign of modern engineering. It delivers unequaled power and torque by combining concussive impacts with spinning force. Because of this unusual combination, the impact driver can handle difficult screws in a variety of applications with exceptional ease.

As we work through this comparison, it’s clear that selecting one of these tools affects more than just personal taste; it also changes the activities that are performed in the ever-changing world of hardware tools. The transition from cordless to traditional impact drivers represents a paradigm shift in our approach to project management, as well as a change in the tools we use.

The Screwdriver Evolution

It’s important to understand the history of the venerable screwdriver in order to appreciate the differences between a standard screwdriver and a Bosch Cordless Impact Driver. In the past, turning a manual screwdriver required human effort. This method worked well for smaller jobs but was frequently laborious and physically taxing when working with larger or more durable materials.

Through the addition of electric or battery-powered mechanisms for quicker and more effective screwdriving, the power screwdriver aimed to overcome these constraints. But impact drivers delivered more force and variety than even power screwdrivers could.

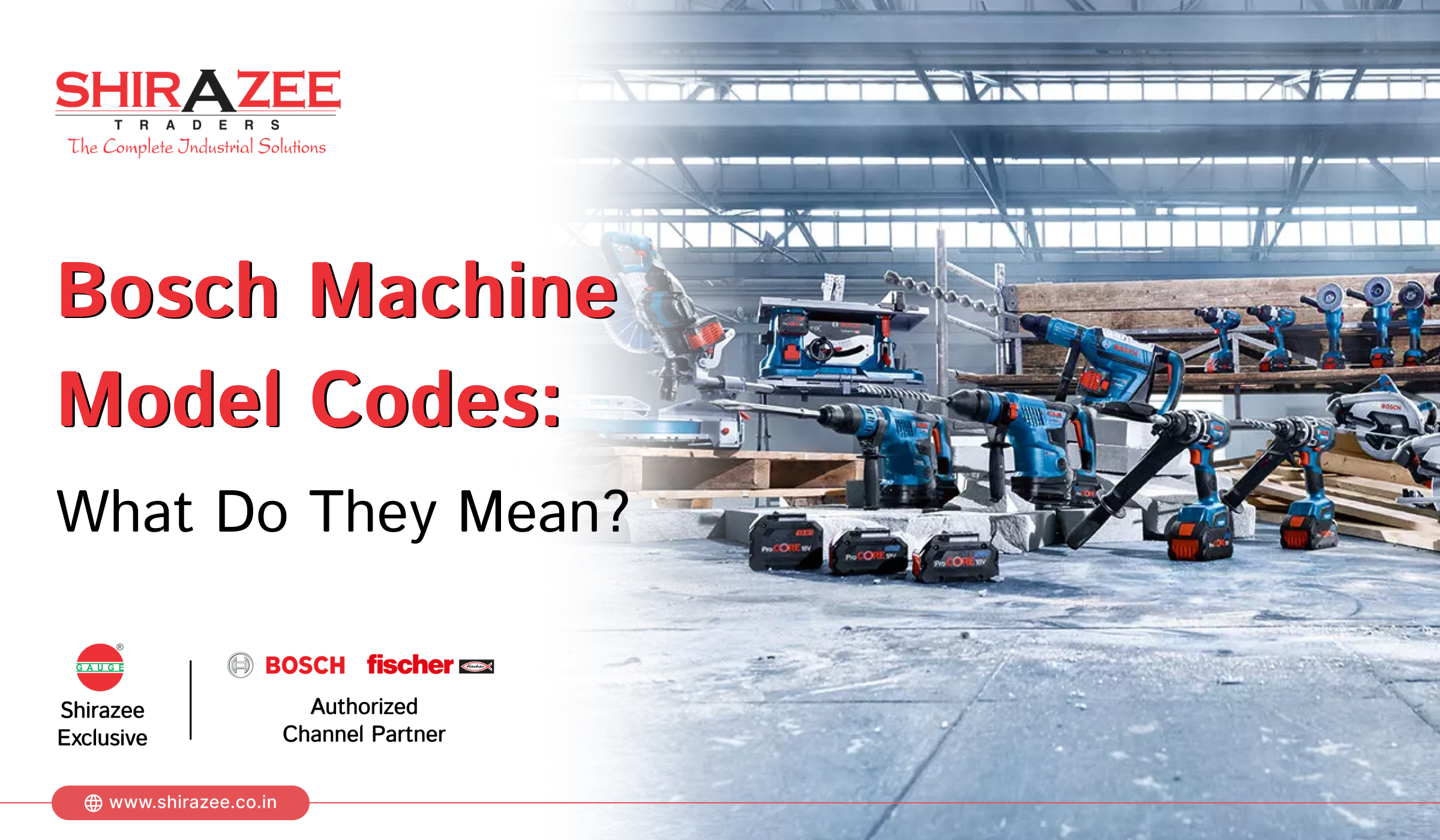

The Bosch Cordless Impact Driver

1. Power and Grip

Designed to provide unparalleled power and grip, the Bosch Cordless Impact Driver is the crucial component of engineering. The impact driver combines rotating power with concussive blows, which allows it to easily remove even the most obstinate screws, in contrast to ordinary screwdrivers that only use rotational force. Bosch impact drivers are an essential tool for heavy-duty applications because of their remarkable high torque output.

2. Cordless Freedom

The Bosch Cordless Impact Driver is groundbreaking because it frees users from cables. Because they are convenient and portable, cordless tools have become more and more popular. They let users move around their workstations freely without being connected to a power source. This is a huge benefit, especially in locations without easy access to electrical outlets or on building sites.

3. Battery Technology

Bosch, a leader in power tool innovation, incorporates cutting-edge battery technology into their cordless impact drivers. These instruments run on lithium-ion batteries, which are renowned for having a high energy density and longer life cycles. Because of the battery’s efficiency, longer usage intervals between charges are possible, guaranteeing continuous productivity.

4. Variable Speed and Accuracy

Bosch impact drivers frequently have variable speed settings, giving users exact control over the operation of the instrument. This degree of accuracy is very useful when handling fragile objects or when using a gentle touch. Without this capability, traditional screwdrivers could find it difficult to match the sophisticated control provided by modern versions.

Conventional Screwdriver: A Classic Innovation

1. Manual Operation

To rotate the tool and drive screws into materials, a traditional screwdriver must be used manually, requiring the operator to exert physical force. Manual screwdrivers work well for small jobs, but they can become tedious and unusable for larger ones.

2. Limited Power

The power and torque of conventional screwdrivers are restricted since they do not have an impact mechanism. When faced with resistive surfaces or screws embedded in dense materials, they might have trouble.

3. Versatility

Despite their drawbacks, manual screwdrivers are still a popular option for precise work due to their versatility. They work well in situations where delicacy and caution are essential, including putting in tiny fixtures or assembling intricate circuitry.

The Effect on the Market

1. Trends in the Market

Strong cordless impact drivers—such as those offered by Bosch—have had a significant impact on the hardware tool market. Because cordless devices are more convenient and do not require bulky cords, consumers are gravitating toward them more and more.

2. Emergence of Specialized Tools

Due to the increased need for impact drivers, specialized tools that meet particular requirements have been developed. Bosch’s impact driver lineup demonstrates the versatility of these tools with variants designed for a variety of uses, from construction to automotive repair.

3. Import Challenges

Keeping up with market changes and technical advancements presents a challenge for importers of hardware products. Importers’ decisions about what products to introduce into their markets may be influenced by the trend toward cordless equipment, especially impact drivers. For importers to successfully navigate this changing market, it is imperative that they comprehend consumer preferences and the desire for particular qualities.

Conclusion

The difference between the conventional screwdriver and the Bosch Cordless Impact Driver marks a turning point in the history of the hardware tool industry. The power, cordless ease, and accuracy of the impact driver have revolutionized the way jobs are addressed and completed. Although the classic screwdriver is still indispensable for some tasks, technology is driving the market toward increasingly potent, effective, and adaptable instruments. A transformative era is upon importers, consumers, and do-it-yourself enthusiasts alike, where the correct tool can make the difference between a hard effort and a project performed flawlessly. The Bosch Cordless Impact Driver is a monument to the world’s unwavering quest of perfection as we navigate this innovative landscape.