Self-Drilling Screws for Metal: 7 Features that Simplify Projects

posted in Business, Industrial Equipment by admin

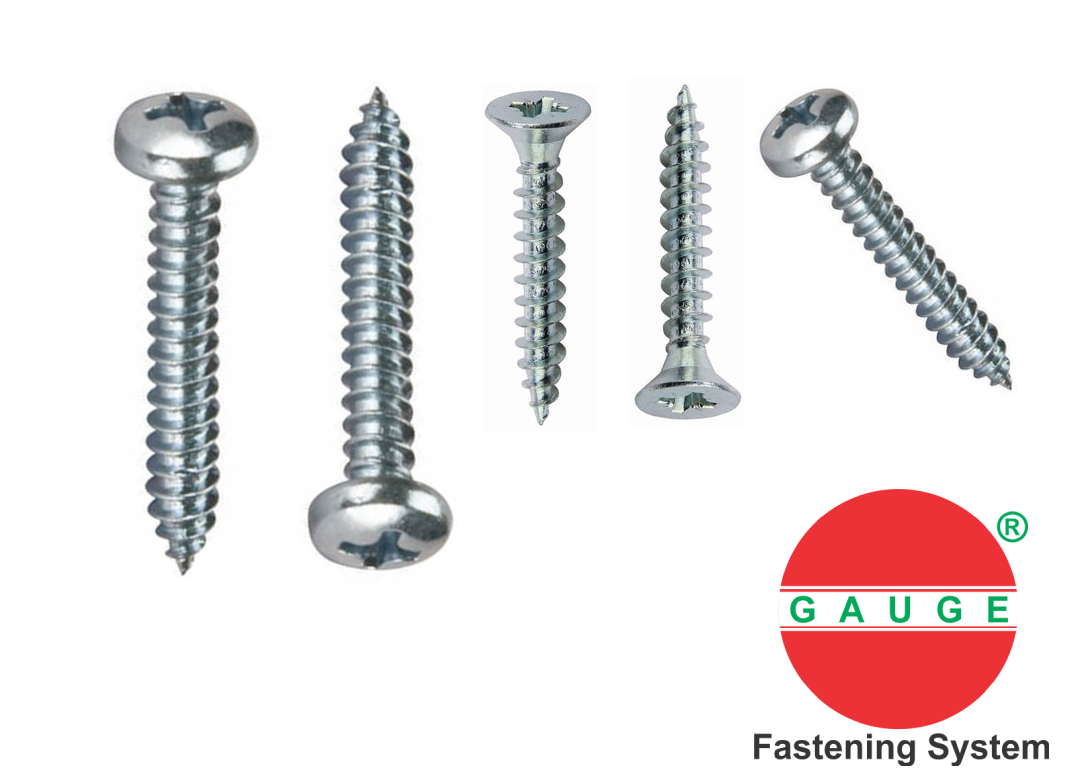

When it comes to DIY projects and construction, having the appropriate tools can make all the difference. In the world of metalworking, self-drilling screws are revolutionary. By doing away with the necessity for pre-drilling holes, these creative fasteners save time and effort on every project. The seven essential characteristics of self-drilling screws that make metal projects easier to complete and a necessity for every toolkit will be discussed in this blog.

1. Self-Drilling Capability

The ability of self-drilling screws to create their own pilot holes as they are pushed into the metal is one of their most notable characteristics. This makes the installation process simpler and does away with the need for additional drilling equipment. Self-drilling screws allow users to save time and labor by simply driving the screw into the metal substrate.

2. Shorter Installation Time

Self-drilling screws, as opposed to conventional screws and bolts, drastically shorten installation time by integrating drilling and fastening into a single step. This is especially helpful for projects that have a tight deadline or when efficiency is critical. Hardware tool suppliers can provide their clients with a quicker and more efficient solution for metal fastening applications by using self-drilling screws.

3. Greater Versatility

Self-drilling screws are extremely adaptable and can be utilized in a variety of metal applications, such as HVAC installations, steel framing, and roofing. Their self-drilling feature allows them to operate in materials with different thicknesses without compromising functionality. Self-drilling screws are a preferred choice for builders, contractors, and do-it-yourselfers due to their versatility.

4. Enhanced Holding Power

When installed correctly, self-drilling screws provide outstanding holding power despite their small size. Strong and secure bonding is produced between the screw and the metal substrate by the self-drilling mechanism. This is necessary to guarantee the metal assemblies’ structural integrity and avoid problems like loosening or failure over time.

5. Corrosion Resistance

A lot of self-drilling screws have coatings made of stainless steel, zinc, or galvanized steel that resist corrosion. Since they are more resistant to rust and corrosion as a result, they are appropriate for outdoor and marine applications where exposure to moisture and other environmental factors is frequent. Providers of hardware tools can give their clients confidence that their fasteners will endure the test of time, even in harsh conditions.

6. Simple Installation

Self-drilling screws also have the benefit of being simple to install. Self-drilling screws can be inserted straight into the metal substrate using a standard power drill or screwdriver, in contrast to traditional screws that need special drilling equipment and precise alignment. This makes installation easier and lowers the chance of mistakes or misalignment, giving the finish a neater, more polished appearance.

7. Economical Resolution

Self-drilling screws are ultimately a more affordable option for metal projects due to their versatility and time-saving features, even though they may initially cost a little more than traditional fasteners. Over time, self-drilling screws provide a high return on investment because they simplify installation and save labor costs. They are therefore a wise option for builders and contractors trying to optimize efficiency and productivity on the job site.

Here are some additional benefits associated with self-drilling screws

Increased Comfort and Safety

Self-drilling screws have practical advantages, but they also have convenience and safety benefits. The self-drilling mechanism makes them easier and more comfortable to use, especially during prolonged periods of fastening, by lowering the risk of hand and wrist fatigue associated with manual drilling. This is especially helpful for professionals who use their tools on a daily basis and for do-it-yourselfers who are working on weekend home improvement projects. Self-drilling screws allow users to work more productively while lowering their risk of strain or injury, making the process safer and more pleasurable all around.

Improved Aesthetics and Finish

Furthermore, in comparison to conventional fasteners, self-drilling screws help create a finish that is neater and more visually pleasant. Self-drilling screws produce a neater appearance with fewer noticeable drill marks or surface imperfections because they do not require pre-drilling holes. This is particularly crucial in applications like furniture assembly, interior finishing, and architectural metalwork where aesthetics are valued highly. Self-drilling screws add value and distinction to any project by producing a seamless and polished result that improves the overall quality and visual appeal of the finished product.

Contribution to Sustainability and Environmental Responsibility

Self-drilling screw adoption also fits in with larger industry trends in the construction sector toward sustainability and environmental responsibility. Self-drilling screws help reduce waste and resource consumption by lowering the number of tools and materials needed for metal fastening, leading to a more environmentally friendly method of building and construction. Furthermore, self-drilling screws help structures last longer and be more resilient over time by resisting corrosion and requiring fewer repairs or replacements due to their long-lasting durability. Self-drilling screws are a more environmentally friendly option for both builders and contractors because they not only save time and money but also lessen the overall impact of construction activities.

Conclusion

Self-drilling screws are an invaluable addition to any toolbox because they have a number of features that make working with metal easier and more efficient in general. Self-drilling screws are a dependable solution for a variety of applications because of their self-drilling ability, quicker installation times, adaptability, holding power, and resistance to corrosion. Hardware tool suppliers can satisfy the increasing demand for these cutting-edge fasteners by providing their clients with superior products that offer outstanding value and performance. Self-drilling screws make metal projects easier, faster, and more affordable to finish, which benefits builders, contractors, and do-it-yourselfers alike.