Self-Drilling Screws for Metal: 5 Features that Simplify Projects

posted in Industrial Equipment by admin

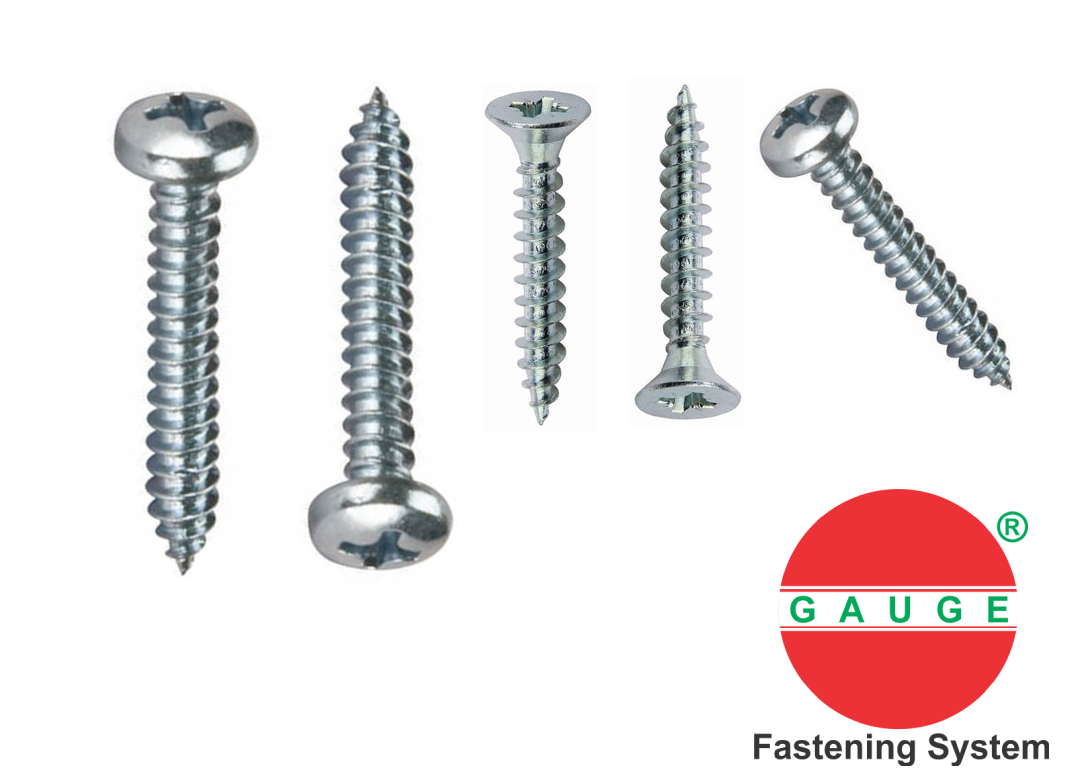

The use of self-drilling screws in metal applications has revolutionized construction and manufacturing processes, so it is critical for top suppliers and exporters of hardware products to understand what makes them unique. This brief guide examines the five key elements that set self drilling screws apart as the preferred option for professionals. Every quality that makes metal projects more efficient includes their adaptability to a wide range of materials, their capacity for simultaneous drilling and fastening, their resistance to corrosion, improved torque and grip, and their availability in a variety of sizes and types.

These features help professionals by optimizing project outcomes and streamlining their processes. Highlighting the benefits of self-drilling screws highlights the company’s dedication to offering premium hardware products that are suited to the changing needs of the manufacturing and construction sectors.

1. Versatility in Material Compatibility

The material compatibility of self-drilling screws is remarkably versatile. These screws don’t require pre-drilling because they are designed to pierce and adhere to a variety of metal surfaces. Because of this feature, they can be used with a variety of metal materials, such as stainless steel, aluminum, and steel. The self-drilling screw’s versatility makes it easier to complete projects involving steel frame construction, roofing, or metal panel installation by removing the need for the labor-intensive step of drilling pilot holes.

Moreover, the versatility of these screws highlights how important they are in meeting the various demands of professionals in manufacturing and construction. Their versatility is greatly enhanced by the flexibility they provide, which makes them a dependable option for a broad range of projects.

2. Efficient Drilling and Fastening in One Step

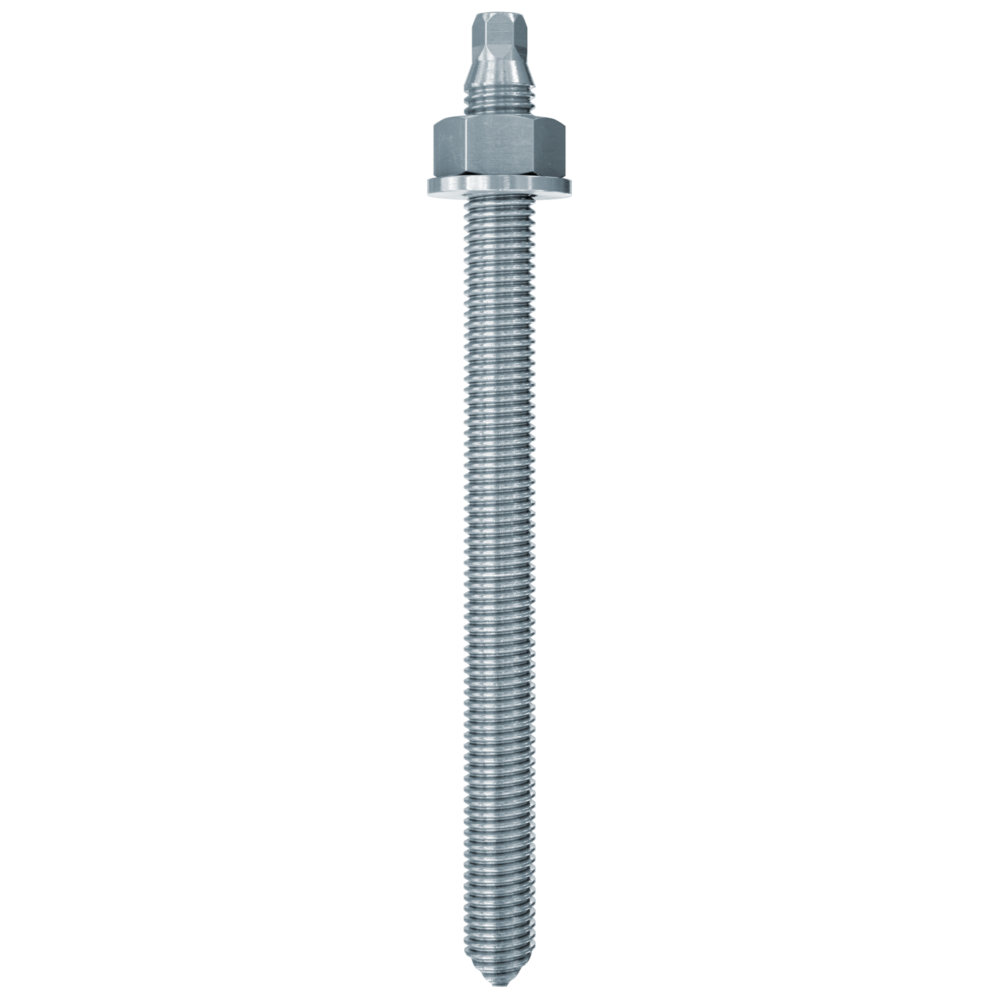

Self-drilling screws are unique in that they can be fastened and drilled at the same time. These screws, which have a drill bit at the tip, drill pilot holes on their own when they press into the metal surface. Their ability to save time and increase efficiency makes them the go-to option for projects where accuracy and speed are essential. Self-drilling screws save professionals time and allow them to concentrate on other important aspects of their projects.

The ability to drill and fasten at the same time not only saves time but also improves the project’s overall accuracy. Separate drilling and fastening steps can lead to errors, but the screws guarantee a smooth and secure connection. In large-scale manufacturing or construction projects, where every step must be optimized for maximum productivity, this efficiency is especially important.

3. Corrosion Resistance factor for Longevity

In metal projects, corrosion is a major concern that is successfully addressed by self-drilling screws. Excellent corrosion resistance is often provided by the coatings or materials that come with these screws. The coatings guarantee the screws’ longevity and durability by preventing rust and deterioration. Self-drilling screws can be used in a variety of indoor and outdoor applications thanks to this feature.

Furthermore, self-drilling screws’ resistance to corrosion increases the longevity of the entire product or structure. Whether they are utilized in manufacturing equipment or building construction, screws add to the final product’s dependability and longevity. This emphasizes even more the value of self-drilling screws in metal applications for experts looking for strong and long-lasting fastening solutions for their projects.

4. Enhanced Torque and Grip

The efficacy of any metal project depends on the stability and reliability of the fasteners used. Self-drilling screws have been designed to provide improved torque and grip, guaranteeing a strong and stable attachment. This feature is especially crucial in situations where loads, vibrations, or outside forces could compromise the structural integrity of the object. Self-drilling screws’ capacity to hold fast under difficult circumstances improves the project’s overall structural stability, boosting professionals’ confidence and ensuring the long-term success of the building or manufacturing project.

Moreover, self-drilling screws are appropriate for applications where structural integrity is critical due to their increased torque and grip. Experts can rely on self-drilling screws to give the required support in situations where the fasteners’ strength determines the stability of the entire structure. This characteristic becomes especially important for construction projects where dependability and safety are essential.

5. Wide Range of Sizes and Types

Different metal projects have different fastener requirements. In order to meet this diversity, self-drilling screws come in a large variety of sizes, lengths, and types to suit a range of applications. Professionals can select the ideal fastener for their particular needs when they have access to a wide range of self-drilling screws, regardless of the size of the project whether it’s a small-scale DIY project or a massive industrial construction. This flexibility is essential for satisfying the needs of various industries and guaranteeing that experts can locate the ideal self-drilling screws for their projects.

Furthermore, the variety of sizes and types that are available indicates the adaptability of self-drilling screws. Experts are able to choose the best screw for their project by taking into account various aspects like material thickness, load-bearing capacity, and structural design. Because of their versatility, self-drilling screws can be easily incorporated into a wide range of projects, which makes them a dependable and useful option for professionals in a variety of industries.

Conclusion

In conclusion, self-drilling screws are widely used in metal projects because of their efficiency, adaptability, resistance to corrosion, increased torque, and variety of sizes. As a hardware exporter and supplier of self-drilling screws, putting these features first in your products makes them appear dependable, effective, and appropriate for a range of uses.

Professionals from a variety of industries look for fasteners that will make their projects easier and increase their chances of success overall. With their cutting-edge features, self-drilling screws continue to satisfy these needs and offer effective solutions for manufacturing and construction projects all over the world. Self-drilling screws will likely become more and more important in metal applications as the construction and manufacturing industries develop, securing their position as essential tools for professionals seeking efficiency, accuracy, and durability in their projects.