Rivet Evolution: A Deep Dive into Types, Uses, Materials, and Workings

posted in Blind Rivets, Industrial Equipment by admin

For generations, rivets have been essential to the manufacturing, construction, and other industries. These ostensibly straightforward fasteners have undergone tremendous evolution in response to the shifting demands of many applications. In this in-depth look at rivets, we will examine the numerous types, components, and mechanisms of rivets, illuminating their significance in contemporary manufacturing and construction operations.

What is a Rivet?

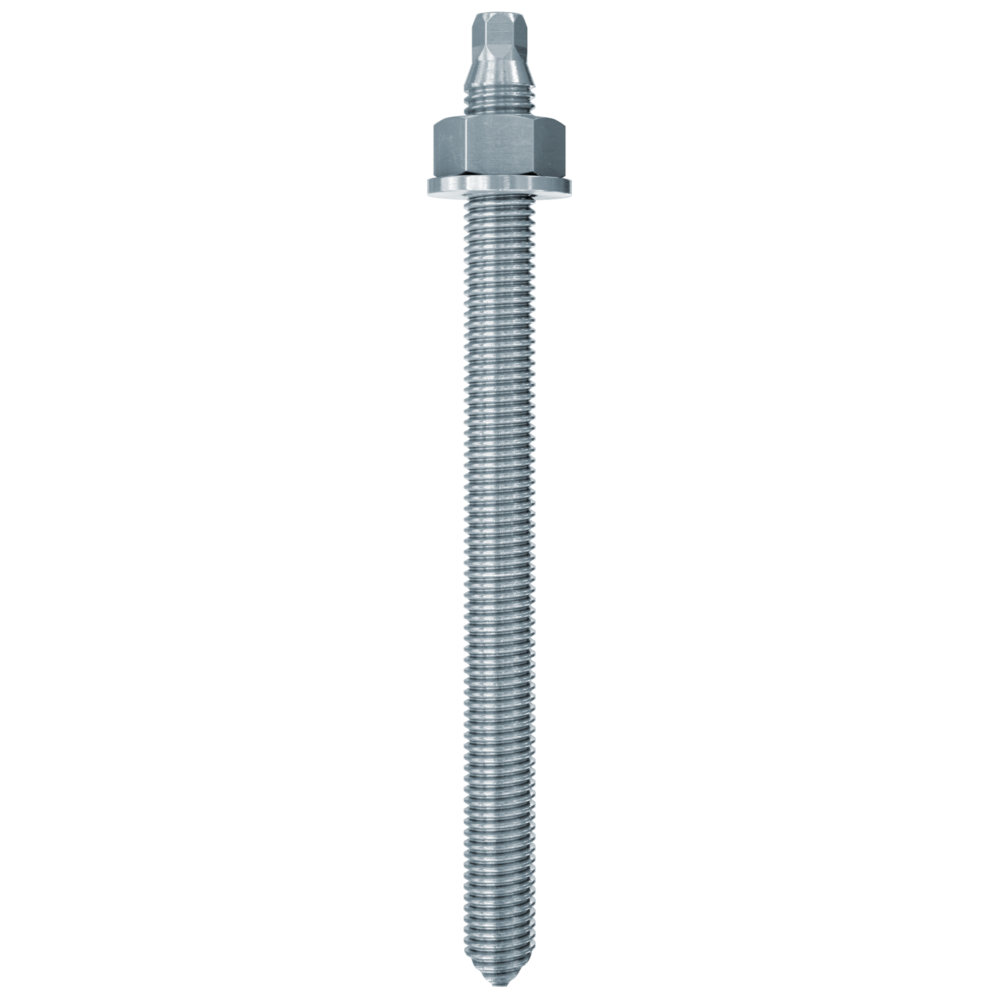

Rivets are a basic and reliable mechanical fastener that are utilized in several industries and applications all over the world. A rivet is essentially an iron pin or rod with a head and an extension on one end. A river’s main function is to permanently link two or more materials, forming a strong connection that can endure a variety of stresses and environmental factors. The fundamental idea of riveting is rather straightforward but extremely powerful. A hole must first be bored through the materials being joined in order to use a rivet. Following that, the rivet is placed into the hole with the head on one side and the tail on the other. The tail end of the rivet is bent or “set” using a specialized tool called a rivet cannon or riveter. In the procedure known as “rivet setting” or “rivet clinching,” the tail end flattens and expands, thereby locking the components in place and creating a watertight seal.

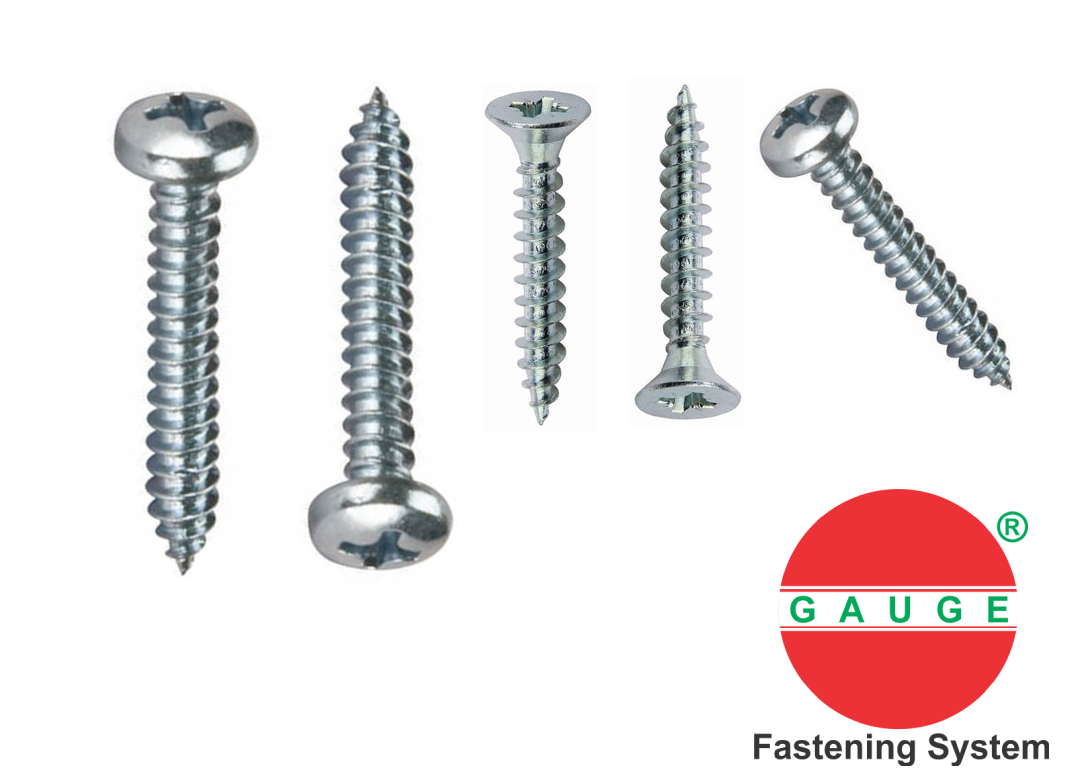

There are many different varieties of rivets, each created for certain uses and specifications. One of the earliest and most common types of rivets are solid rivets, which are solid metal pins without a preformed head that must be manually created with a hammer or press. Pop rivets are a more contemporary and adaptable alternative that can be used in circumstances with restricted access because they can be inserted from one side of the workpiece. The capacity of rivets to offer a durable, vibration-resistant connection is one of their unique qualities, making them perfect for usage in heavy machinery, aircraft, automotive, construction, and numerous other industries. They perform well in settings where utmost structural integrity and dependability are required, and they can tolerate heavy loads, high temperatures, and harsh climatic conditions.

Types of Rivets

Rivets are necessary mechanical fasteners that are available in a variety of varieties to fit a variety of purposes. Solid rivets are unheaded pins that need to be manually shaped with a hammer or press. They are the oldest and most common type of rivet. Pop rivets, commonly referred to as blind rivets, are a relatively recent invention that may be attached to a workpiece from only one side, making them perfect for circumstances where there is limited access. Tubular rivets have a hollow shaft and are frequently used in leathercraft and jewelry. They are fastened by smashing the end into a flat shape. On the contrary hand, drive rivets, which are frequently found in assembly lines, provide a quick and effective approach to join materials. From the structural dependability of solid riveting to the ease of blind rivets when mobility is a problem, every kind of rivet has distinctive qualities that cater to particular needs. The needs of the application, the components being joined, and the required amount of stability in the connection between them all influence the type of rivet that is used, making rivets a diverse and essential part of engineering, manufacturing, and building.

Material and working of Rivets

Rivets are adaptable mechanical fasteners having numerous uses, including in the construction and aerospace sectors. They act as strong connectors to firmly affix materials together. These fasteners are available in a variety of forms, each serving a different purpose, such as solid rivets, drive rivets, tubular rivets, and pop rivets (also known as blind rivets). Traditional options include solid rivets, which are solid metal pins that must be manually shaped using hammers or presses. They are perfect for structural connections because of their durability and strength. Pop rivets, also known as blind rivets, are a contemporary invention created for circumstances when there is restricted access to the rear of the workpiece. They are frequently employed in automobile and aviation industries and are frequently found in modern buildings.

Choosing the right rivet material is essential to the riveting procedure. Mild steel blind rivets are a common option for many applications because of their cost and durability. Aluminum multigrip blind rivets are appropriate for locations where weight and durability are important considerations because they are lightweight and corrosion-resistant. Blind rivets made of stainless steel perform well in tough environments like the chemical or marine industries because of their remarkable corrosion resistance. Digging a hole into the substance that needs to be bonded, then inserting the rivet, is the riveting procedure. The rivet is deformed or “set” using a specialized tool that is frequently referred to as a rivet gun. This procedure involves shaping the head of the rivet on one side of the material and flat the tail on the other. In pop riveting, a mandrel is pulled through the hollow shaft of the rivet by the rivet gun, expanding the tail end and producing a safe, blind attachment. Inspections and quality control are crucial to ensuring the reliability and security of the final item. For a riveting operation to be effective, selecting a trustworthy blind rivets provider and high-quality hardware tools is essential. Suppliers are essential in offering a selection of rivet types and materials to meet various needs. Strong and long-lasting connections are ensured by the use of hardware tools, such as rivet guns and rivet nut tools, which allow for efficient and accurate rivet placement.

Conclusion

We have examined all aspects of rivets in this thorough blog, including their historical significance, many varieties, material options, the riveting method, and contemporary applications. Rivets continue to develop, adapt, and play a critical role in attaching materials securely and dependably in the construction, manufacturing, and engineering industries. Understanding the development and adaptability of rivets is essential to appreciate their lasting significance in our industrialized society, whether you’re an engineer, manufacturer, or someone who is just interested in the field of fasteners. Essentially, rivets hold the world’s facilities, buildings, vehicles, and machines together silently but resolutely. They are the unnoticed heroes of modern engineering and construction. They have established themselves as a classic and essential element in the field of fasteners and mechanical links because of their tried-and-true design and durable performance.