Installing blind rivets is a simple procedure. Prior installing rivets the following things must be taken into consideration.

Materials: The determination of the type of blind rivet is dependent on the material. The softness or hardness of the material can change the rivet type.

Rivet Material: Rivet material is chose on the basis of environmental factors, strength, corrosion resistance and installation materials.

Head type: Appropriate head type should be chosen while installing blind rivets

Rivet Length: Accurate rivet length should be chosen while installing blind rivets as the length of the rivet will change the grip rang.

Rivet Diameter: Determines the size of the hole that needs to be drilled

Grip Range: Grip range is the range of the thickness of the material for proper installation

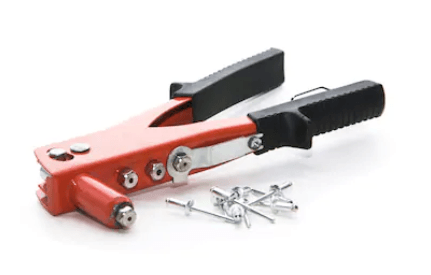

Installing Blind Rivets

Blind rivets are installed using a riveter aka pop riveter or rivet gun as show below

Step 1: Clamping Material

While clamping the material together, make sure they are aligned in line with each other having no gaps

Step 2: Drilling

Drill bit should be of right size. Drill through the material making a hole for the rivet to go through the clamped material.

Step 3: Placing Rivet

Place the head of the rivet through the hole so that the mandrel is pointing upwards.

Step 4: Placing the riveter

Push the nozzle of the riveter onto the mandrel of the rivet

Step 5: Using the Riveter

Now squeeze the handles of the rivet gun together which will break the mandrel out. This will pull the head into the rivet causing the end of the rivet to expand.

Now the rivet will be permanently fixed holding the materials together.